Frequently Asked Technical Questions

We are finding it difficult to design permanent diagonal bracing for scissors trusses. The truss is often only a few feet in depth, which does not provide adequate room for diagonal bracing. Has SBCA come up with recommendations for permanent bracing of scissors trusses?

The truss industry maintains that the design of truss roof and floor system permanent bracing is the responsibility of the building designer. System permanent bracing covers the entire structure and all bracing element interactions.

An exception to this is identifying the locations of compression web bracing. Compression web bracing is different because, as designers and manufacturers, we are taking responsibility for the design and structural performance of the individual components. We must make certain that each truss is designed and built to support the loads stated on the truss design drawing.

Compression web bracing generally takes the form of continuous lateral web bracing. If it is required on a truss, the truss designer will point out the location on the truss design drawing. To avoid this from being overlooked in the field, manufacturers may also indicate the location of the brace directly on the truss by using an SBCA bracing tag. This lateral brace stabilizes the web, decreases its tendency to buckle under compression forces and allows the web to reach its full design capacity. What happens when permanent lateral bracing is not possible to use for the given truss system or individual truss type?

The following question deals with alternatives to continuous lateral braces for webs. What is T-bracing? What is it used for?

How do I, as a truss manufacturer, adequately advise my customer against the dangers of 60 ft. and over truss span installations?

I almost always see wood trusses erected with no stability bracing at points of support. It seems to me that common sense and section 3.3.3.4 of The American Wood Council’s National Design Specification for Wood Construction (NDS) require that lateral support be provided at points of bearing. Plywood decking doesn't provide any more restraint for a wood truss than it does for a roof joist. I doubt if it was a concern with short span trusses having 4 in. high heels, but I see lots of longer span trusses with energy heels that are not braced. At times, it is hard to draw the line between an energy truss and a bottom chord bearing truss. When a truss can clearly be identified as bottom chord bearing, there is not as much resistance to bracing it. When I tell someone that the trusses should be braced, I cannot point to a code requirement that specifically addresses this facet of bracing. Is there any published guidance on a requirement for this type of bracing?

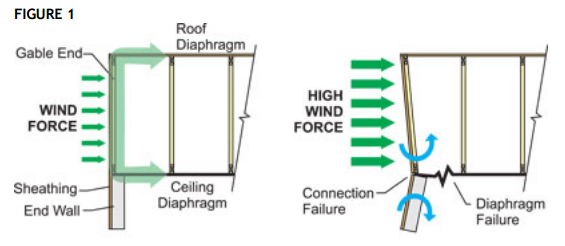

Manufactured gable ends are actually frames even though they are often referred to as trusses. The webs are “studs” oriented vertically and usually spaced at 12, 16 or 24 in. O.C. The gable end frame is designed to transfer vertical loads from the roof to the continuous bearing wall below. Another way gable end frames are different from trusses placed in the interior of the structure is that frames experience perpendicular wind loads. The sheathed frame transfers the wind loads to the roof and ceiling diaphragms and vice versa. The roof and ceiling diaphragms transfer shear loads to the gable end frame, which transfers these loads to the end wall below and into the foundation. In order to do this, the frame relies upon well-designed connections to the bearing wall and diaphragms. If the wind load is high enough and the vertical studs are long enough, the frame may also require a brace to prevent it from rotating the frame and/or buckling the verticals (see Figure 1). This is essentially the same concept as permanent web bracing; therefore, the truss designer is responsible for indicating the location of the bracing for the vertical studs. The building designer is responsible for designing the size and attachment of the brace and how it transfers all the forces into the structure. For gable ends, what is the maximum length a vertical member can be before a lateral brace is required?

We are having a house built and on a recent visit we brought along a friend who builds houses for a living. He noticed that the trusses were wet and a bit moldy. The wood seemed warped, brown, and had white splotches on it. We are worried that it would later make the roof uneven. How could we tell how long the trusses have been exposed to the elements? What options do we have from here? Do we request new trusses, or can these be repaired?

I would like to know the proper storage and shipping of wood trusses.

I am looking for strongback bracing requirements for a 12 in. deep residential floor system with trusses in lengths up to 19 ft. Can the strongback bracing end at a truss without tying into an end wall? For instance, can three trusses of a type be tied together by strongbacks, then the next series of different trusses be tied together without having to be tied back to the previous type of trusses?

As a forensic engineer who has investigated numerous collapses of wood truss systems, I find your web site an excellent resource on the proper erection of wood trusses. What are your opinions on steel trusses, particularly with regards to installation and bracing? Do you feel that the installation and bracing techniques utilized for wood trusses are applicable to steel trusses? Do you know if that is the general industry standard or are there specific requirements and guidelines for steel trusses? Is there a particular guideline/commentary available for metal trusses?

Is it common practice for the supplier/distributor of a truss to provide a publication regarding temporary bracing with the delivery of the material?